Healthcare Providers Want Prefabricated Construction

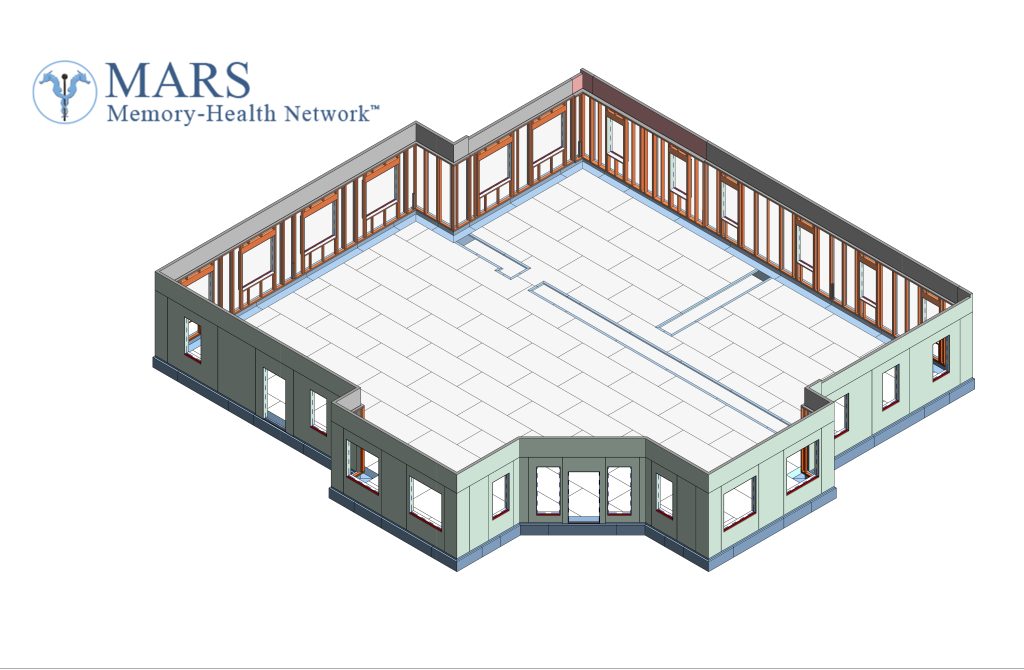

Prefabricated or modular construction is cheaper, faster and creates standardization that can provide a better patient experience.

Prefabricated and modular construction is rapidly rising in popularity for healthcare developers and providers. Modular construction is not only more cost effective and has a faster construction timeline—two benefits that have attracted multifamily and hotel developers—the standardized facilities that come with modular construction also create more efficient operations and provide a better patient experience.

“For integrated teams, there has been a surge in ground-up prefab as a more efficient way of delivering projects,” Stan Chiu of HGA Architects & Engineers, tells GlobeSt.com. “That is about saving time and money, and sometimes could be about increasing quality. You can generally hold that under creating more value. Parallel to that, there is a strategic angle as well. Organizations are looking at prefabrication as a way of returning better value and as a way of establishing standards that will live past the construction and onto the operation of the environment. It is a way of creating consistency from project to project.”

Design teams also see prefabrication as a streamlined approach to construction, particularly in healthcare, which can have a lot of moving parts. “There is a sub benefit of prefabrication, and that is shortening the amount of time that designers spend with users to determine what goes in what room,” says Chiu. “That is a good benefit of having standards. Instead of getting 100 designers to make 100 decisions, we are pulling everyone into a room to make one decisions.”

Standardization is really the key benefit. In healthcare, operating a building is far more costly than construction. Chiu pins it as a 10:1 ration for operations cost versus construction costs. “Standardization is easier to build,” he says. “That could be easier on the development side, but on the operations side, it is a massive benefit. Some organizations see that as a model, and prefab is a fantastic vehicle for delivering that. Providers are coming in and everything is the same, it is going to create a more effective operation, and operators see that as a way of driving clinical quality.”

There is also a significant decrease in construction time. On a recent project, using modular construction reduced a 27-month timeline by 2.5 months, and saved $2.8 million on a total budget cost of $30 million.

The benefits are vast, and they have driven a new demand for modular healthcare facilities. “In healthcare, more than half of our clients are asking about, and we have a number of projects going that are all about maximizing prefab,” says Chiu. “It is super prevalent now. It emerged about four years ago, but it is everywhere.”

Original Story by: Kelsi Maree Borland